Selecting the right microbial system for recombinant protein expression is a critical step in biotechnological processes. Each microorganism—Pichia pastoris, Escherichia coli, and Bacillus subtilis—offers unique advantages and challenges, making them suitable for different applications. From rapid growth to complex post-translational modifications, these systems provide tailored solutions for diverse protein production needs. This article explores the strengths and limitations of each organism, helping you make informed decisions for your projects. At Cultiply, we leverage our expertise in bioprocess engineering and microbial systems to optimize every step of your protein production journey, ensuring efficiency, scalability, and precision.

Why Microorganisms Are Essential for Recombinant Protein Production

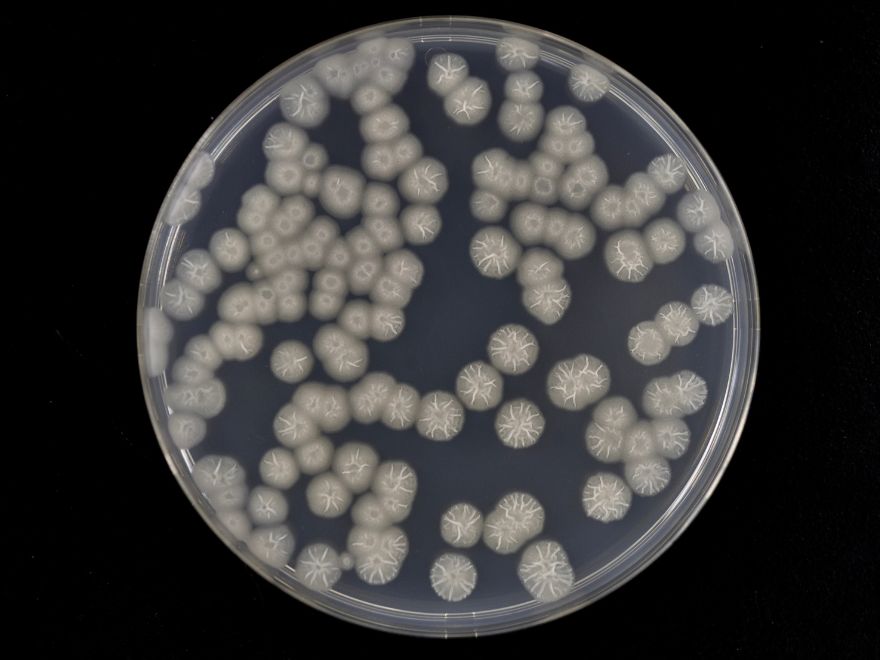

Microorganisms play a pivotal role in recombinant protein production due to their unmatched efficiency and adaptability. Acting as microscopic factories, they convert genetic instructions into functional proteins with remarkable speed and precision. Unlike mammalian or plant-based systems, microorganisms like Pichia pastoris, Escherichia coli, and Bacillus subtilis offer cost-effective and scalable platforms, making them indispensable for research, industrial applications, and pharmaceuticals.

For instance, the fast growth of E. coli reduces production timelines, while Pichia pastoris excels in producing proteins with complex post-translational modifications. Meanwhile, Bacillus subtilis naturally secretes proteins into the medium, simplifying purification processes. These characteristics make microorganisms ideal for producing enzymes, antibodies, and therapeutic proteins.

At Cultiply, we specialize in understanding the nuances of microbial expression systems. By tailoring processes to match the unique requirements of your protein, we ensure high yields, optimal activity, and seamless scalability. The result? Accelerated innovation and a competitive edge for your biotechnology projects.

Key Differences Between Pichia pastoris, Escherichia coli, and Bacillus subtilis

Pichia pastoris: High Yield with Complex Modifications

Pichia pastoris stands out as an exceptional system for recombinant protein expression when post-translational modifications are a priority. This yeast species is capable of performing glycosylation and other eukaryotic-specific processes, making it an ideal choice for producing therapeutic proteins and enzymes that require intricate structural features. Unlike mammalian systems, Pichia can handle high-density fermentation, achieving substantial protein yields without compromising functionality.

Its adaptability to industrial settings is another advantage. Pichia thrives in both shake flask experiments and large-scale bioreactors, offering scalability with minimal optimization. Traditionally, the system supports methanol-inducible promoters like AOX1, enabling tightly controlled expression of the target protein.

However, these advantages come with challenges. Cultivation of Pichia requires specific expertise to manage methanol metabolism and optimize fermentation parameters. Additionally, production costs tend to be higher compared to bacterial systems, as yeast media and bioreactor conditions are more complex.

To overcome these limitations, alternative expression systems in Pichia have been developed that do not rely on methanol induction. Promoters such as GAP (glyceraldehyde-3-phosphate dehydrogenase) enable constitutive expression, simplifying the process and reducing safety concerns and operational complexity related to methanol handling. These methanol-free systems offer a more user-friendly and scalable approach while maintaining high yields and functional protein production.

Despite these hurdles, Pichia pastoris remains a reliable choice for applications demanding high-quality proteins with sophisticated modifications, ensuring results that align with stringent industry standards.

Escherichia coli: Rapid Growth at a Low Cost

Renowned for its simplicity and efficiency, Escherichia coli remains a favorite for recombinant protein production. Its fast growth rate and straightforward genetic manipulation allow researchers to achieve high productivity in a short timeframe. With a doubling time of just 20 minutes under optimal conditions, E. coli enables rapid prototyping and scale-up, making it an economical choice for industrial applications.

The availability of a vast array of molecular tools, including inducible promoters like T7, enhances the flexibility of E. coli for diverse protein production projects. This bacterium is also compatible with various plasmid systems, facilitating the expression of a wide range of proteins.

However, E. coli is not without limitations. Its inability to perform eukaryotic post-translational modifications restricts its utility for certain therapeutic proteins. Furthermore, high expression levels can lead to inclusion body formation, necessitating refolding strategies to recover functional proteins. Despite these drawbacks, Escherichia coli offers an unmatched combination of speed, affordability, and versatility, making it indispensable for projects focused on cost-effective, high-throughput protein production.

Bacillus subtilis: Natural Secretion for Simplified Purification

As a gram-positive bacterium, Bacillus subtilis has a unique advantage in its ability to naturally secrete proteins into the growth medium. This feature simplifies downstream purification processes, significantly reducing production time and costs. Its Generally Recognized As Safe (GRAS) status further positions it as a preferred system for food-grade and pharmaceutical applications.

Unlike Escherichia coli, Bacillus subtilis tends to produce soluble proteins without forming inclusion bodies, resulting in higher yields of functional products. This characteristic makes it particularly suitable for enzymes and other industrial bioproducts. Additionally, its robust physiology allows it to thrive under a wide range of cultivation conditions, ensuring reliability and scalability.

Nevertheless, Bacillus subtilis has limitations in performing complex post-translational modifications, making it less ideal for certain therapeutic proteins. It also requires careful optimization of expression systems and media composition to achieve peak performance. Despite these challenges, Bacillus subtilis stands out as an efficient, secretion-friendly system, offering a streamlined path to high-quality recombinant protein production

How to Choose the Right Microbial Expression System for Your Protein

Selecting the optimal microbial expression system involves balancing the specific requirements of your target protein with the capabilities of the host organism. Consider factors such as the need for post-translational modifications, scalability, cost, and production timelines.

If your protein requires glycosylation or other eukaryotic modifications, Pichia pastoris is an excellent choice, albeit with higher costs and technical demands. For rapid, cost-effective production of simple proteins, Escherichia coli offers unparalleled speed and flexibility. Meanwhile, Bacillus subtilis is ideal when protein secretion is critical for simplifying purification workflows.

Collaborating with experts, like the multidisciplinary team at Cultiply, can make this decision process more efficient. Our expertise in microbial systems and bioprocess engineering ensures a tailored approach, optimizing yields and minimizing bottlenecks. By carefully evaluating the unique characteristics of each system and aligning them with project goals, you can unlock the full potential of recombinant protein production while maintaining cost-effectiveness and scalability.

Microbial Expression Systems: Key Features Comparison

| Aspect | Pichia pastoris | Escherichia coli | Bacillus subtilis |

| Key Advantages | High cell density, performs glycosylation, scalable, well-suited for complex proteins | Rapid growth, easy genetic manipulation, low cost, wide range of molecular tools available | Naturally secretes proteins, GRAS status, suitable for industrial fermentation |

| Key Limitations | Requires precise optimization of growth conditions, higher cost compared to bacterial systems | Limited post-translational modifications, inclusion body formation for some proteins | Limited post-translational modifications, some proteins require strain-specific optimization |

| Post-Translational Modifications | Yes, performs eukaryotic-like glycosylation | No (minimal to none) | No (minimal to none) |

| Protein Secretion | Moderate, requires specific conditions | Limited (usually intracellular) | High (secretes proteins extracellularly) |

| Growth Rate | Moderate (doubling time ~2 hours) | Very fast (doubling time ~20 min) | Moderate (~30-60 min doubling time) |

| Cost Efficiency | Moderate to High (higher initial investment but scalable for industrial use) | Very Low (most affordable system) | Low to Moderate (competitive for bulk production) |

| Scalability | High (suitable for industrial use) | High | High |

| Ideal Applications | Production of therapeutic proteins, enzymes requiring glycosylation | Enzymes, small therapeutic proteins, simple recombinant proteins | Industrial enzymes, bulk production of soluble proteins |